Gallery

Click any photo to view it larger.

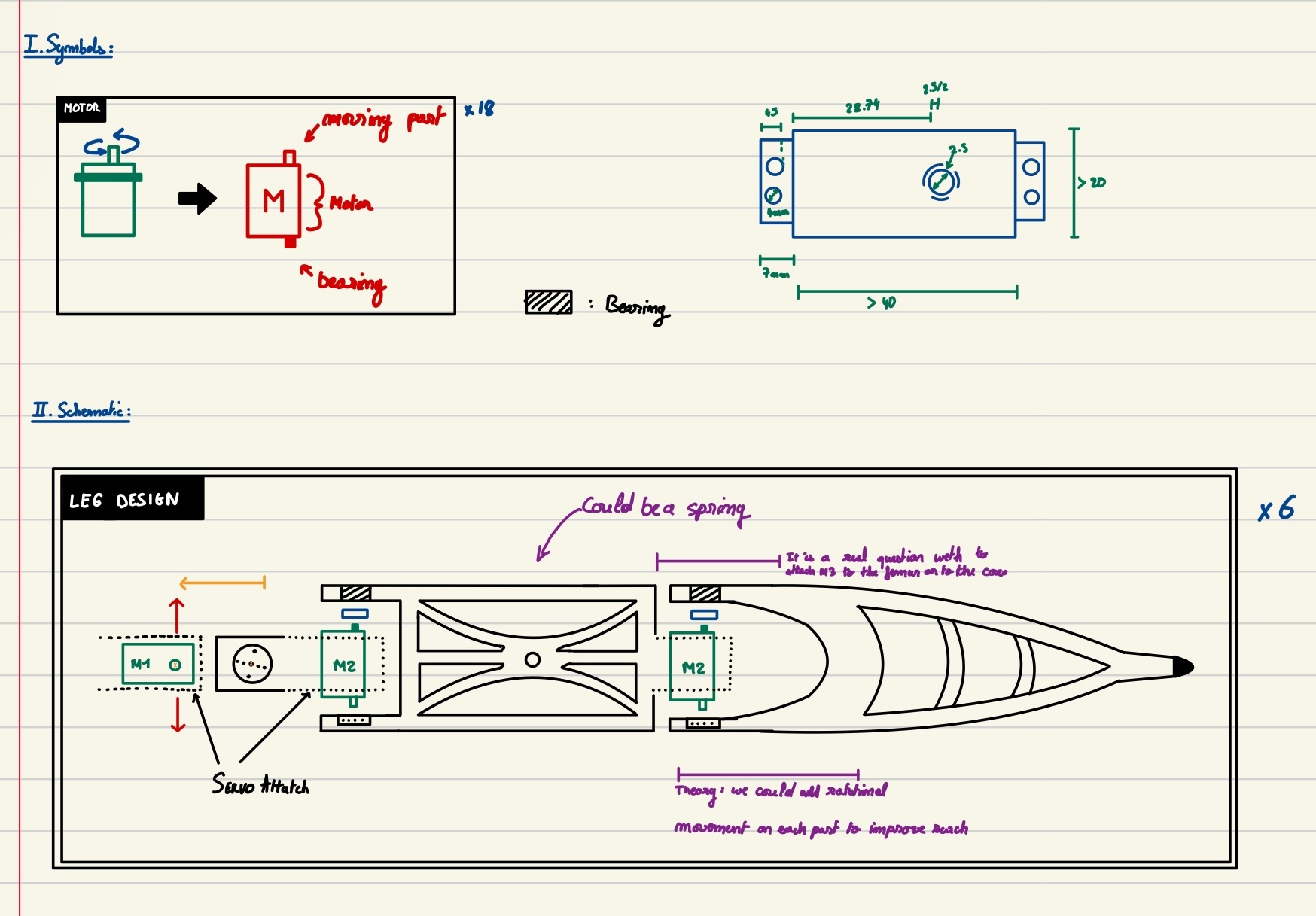

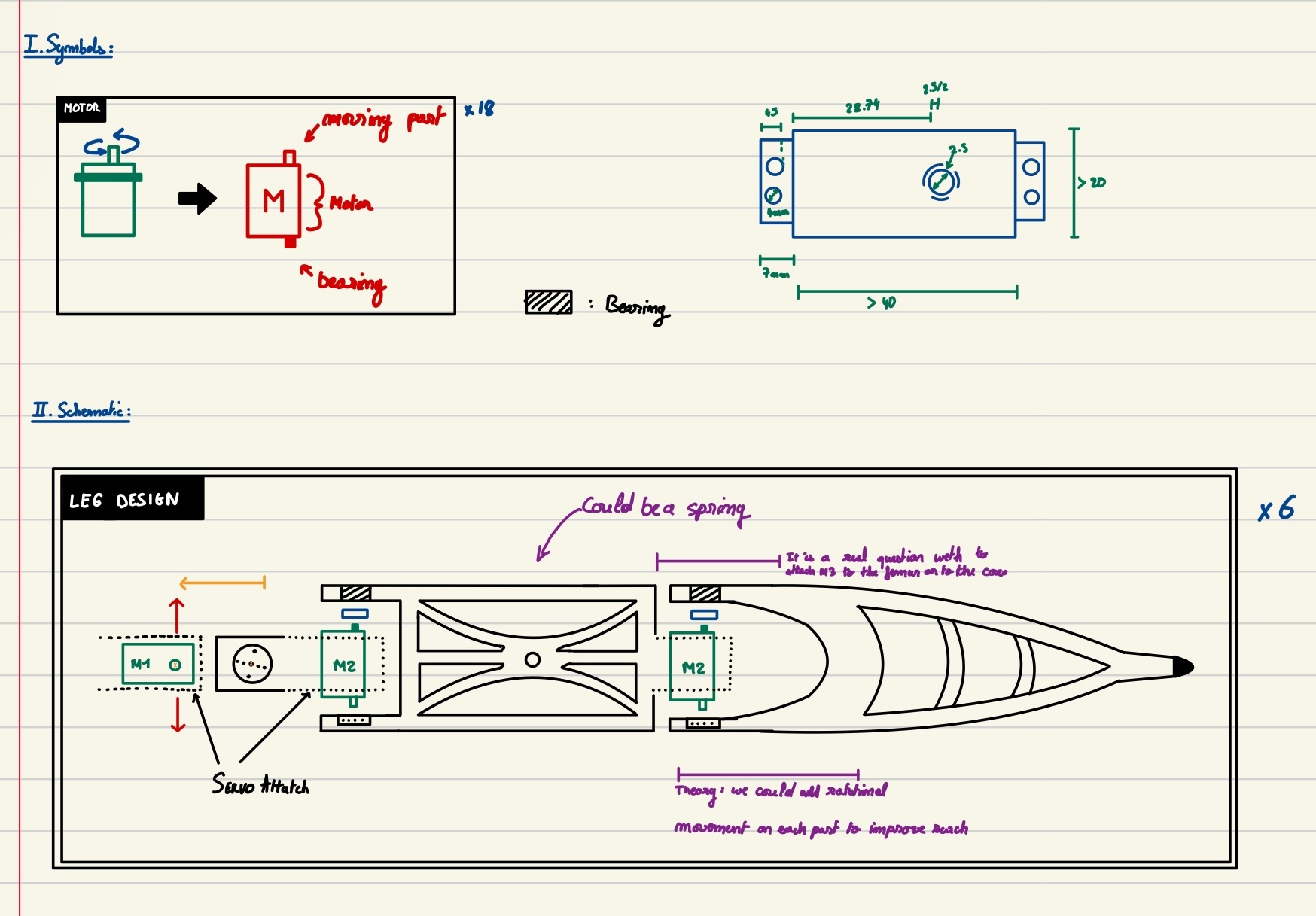

Schematic

Prototype Video

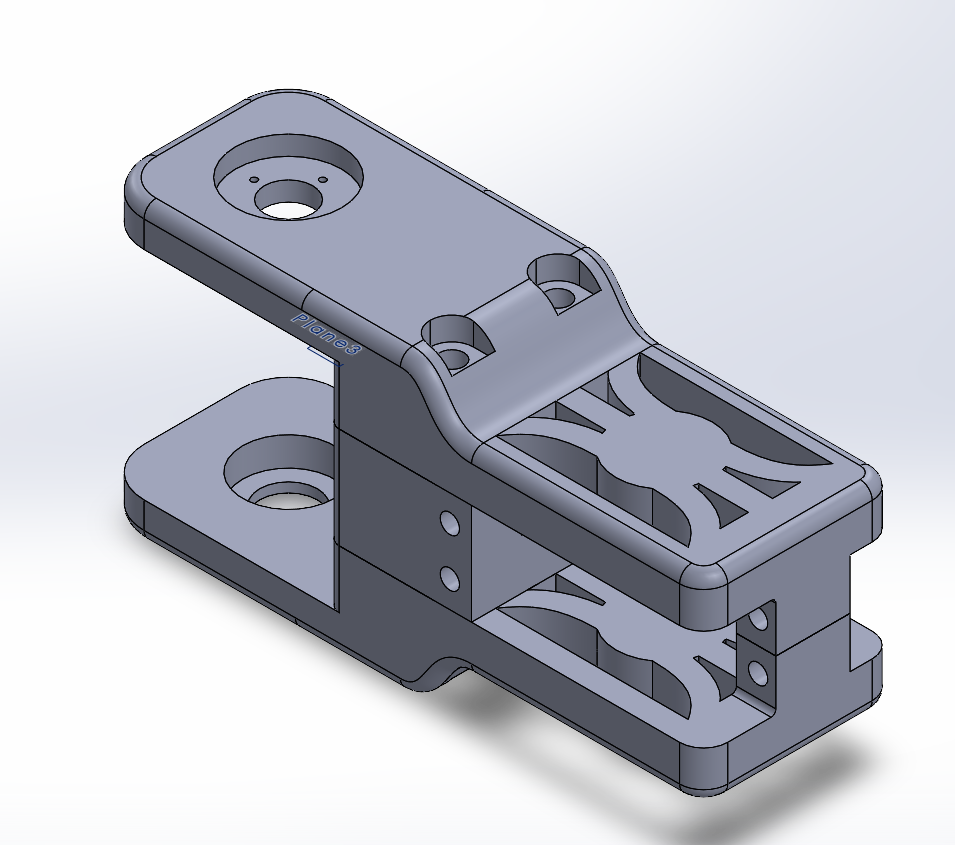

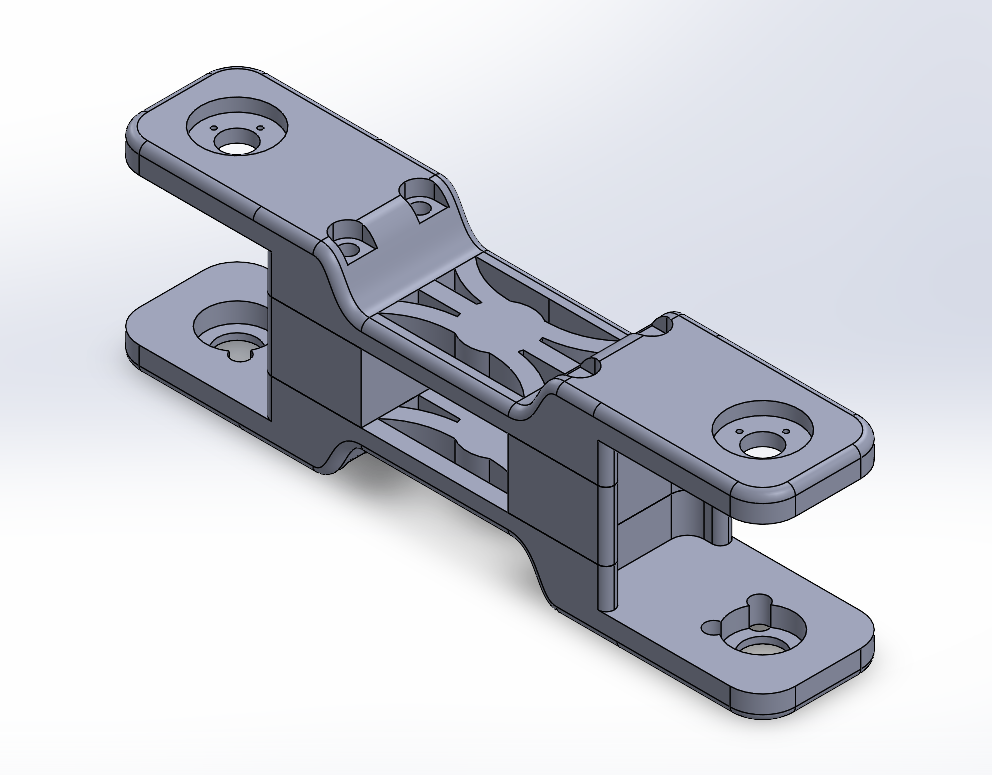

Coxa

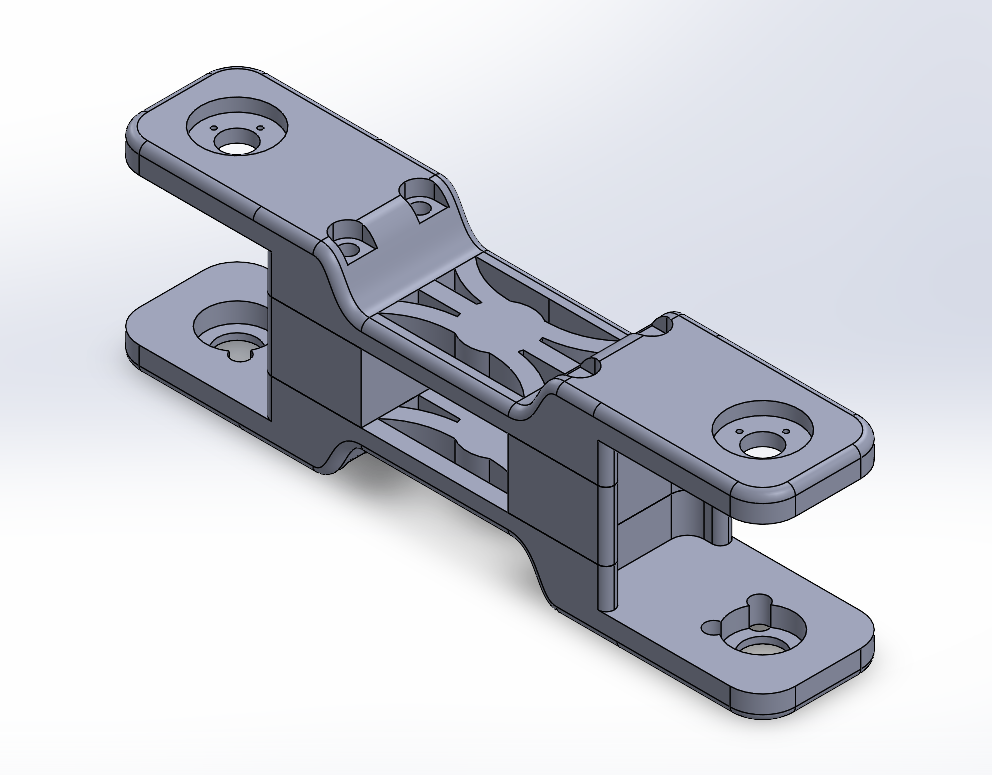

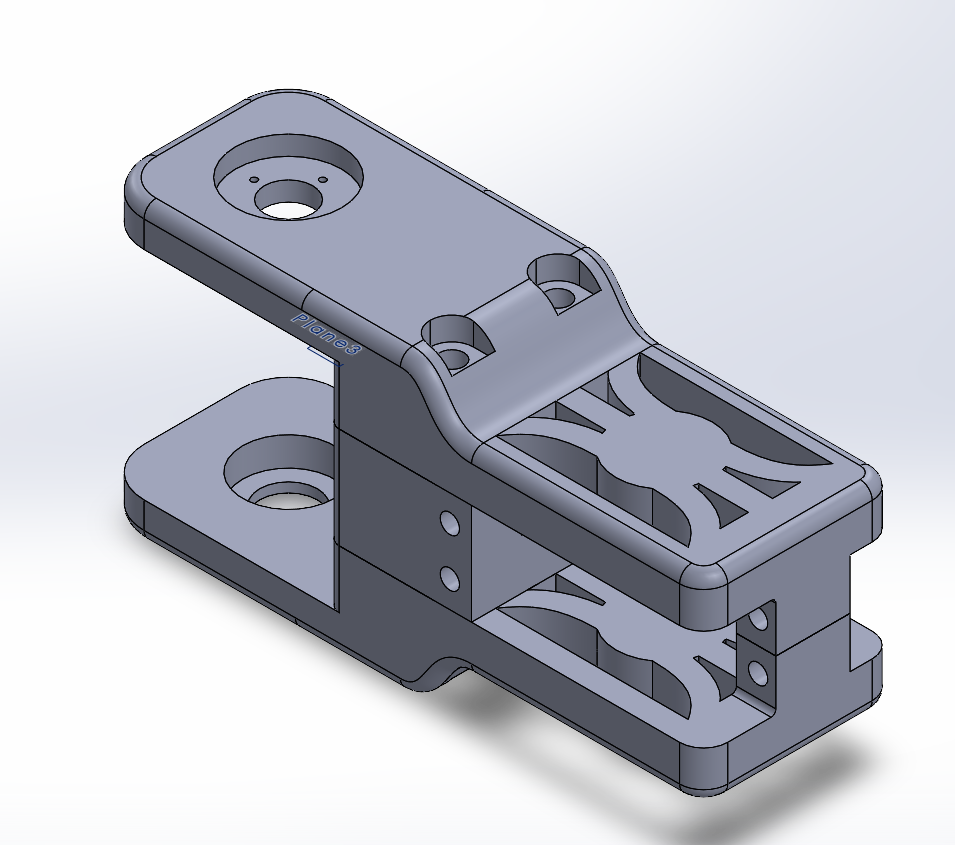

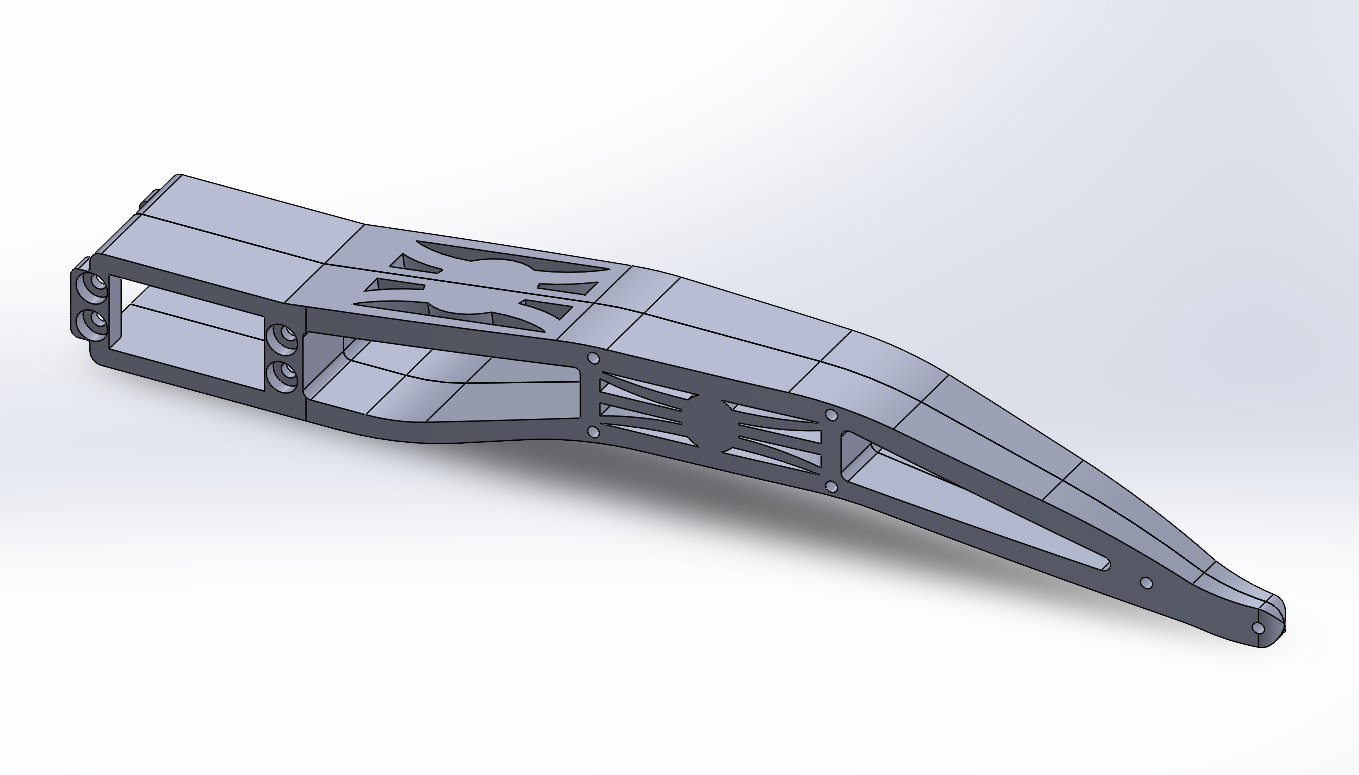

Femur

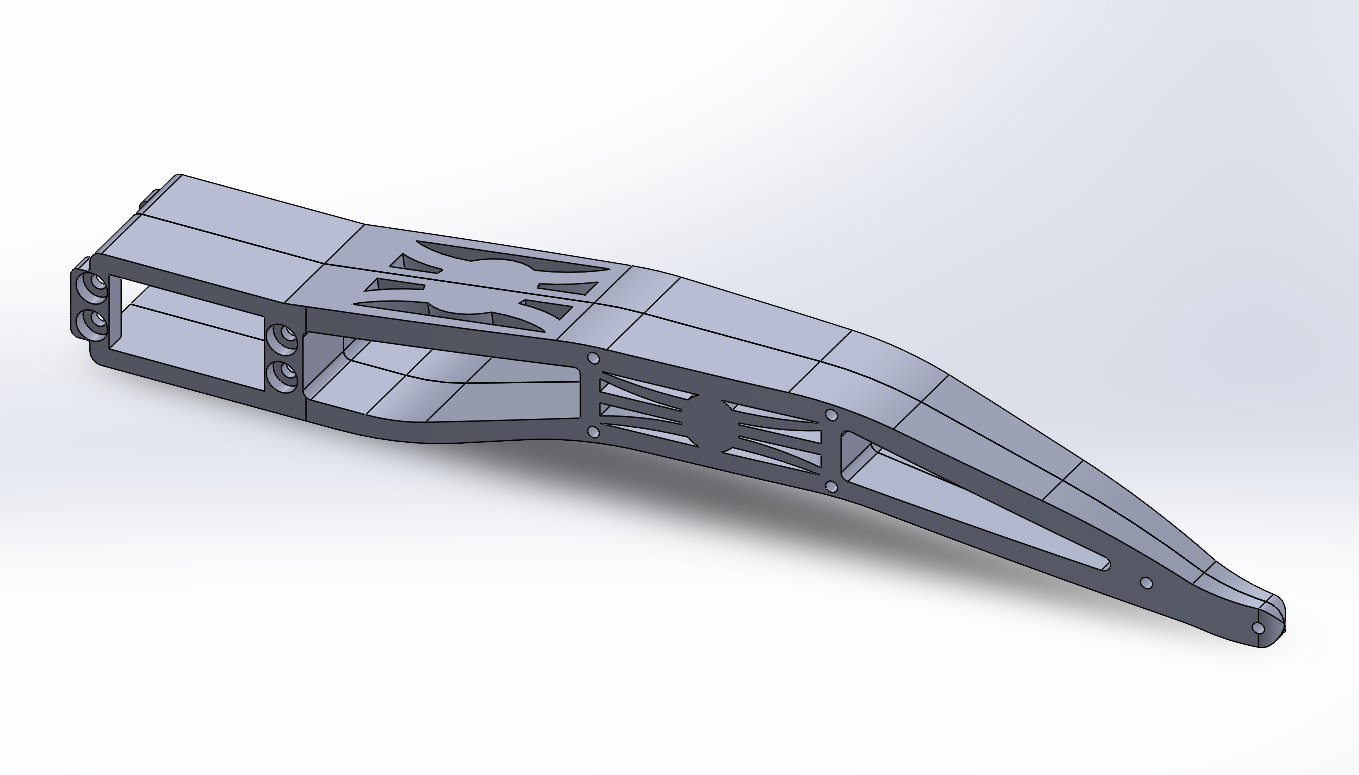

Tibia

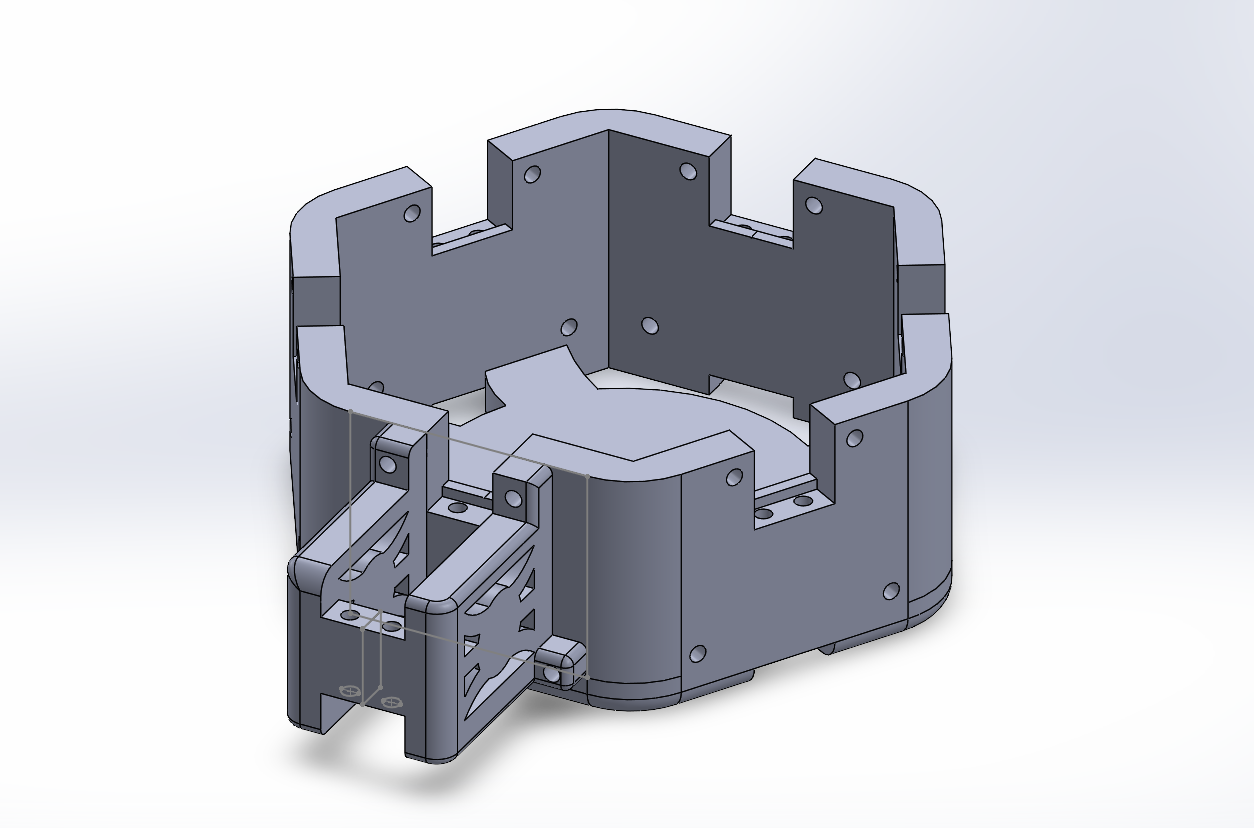

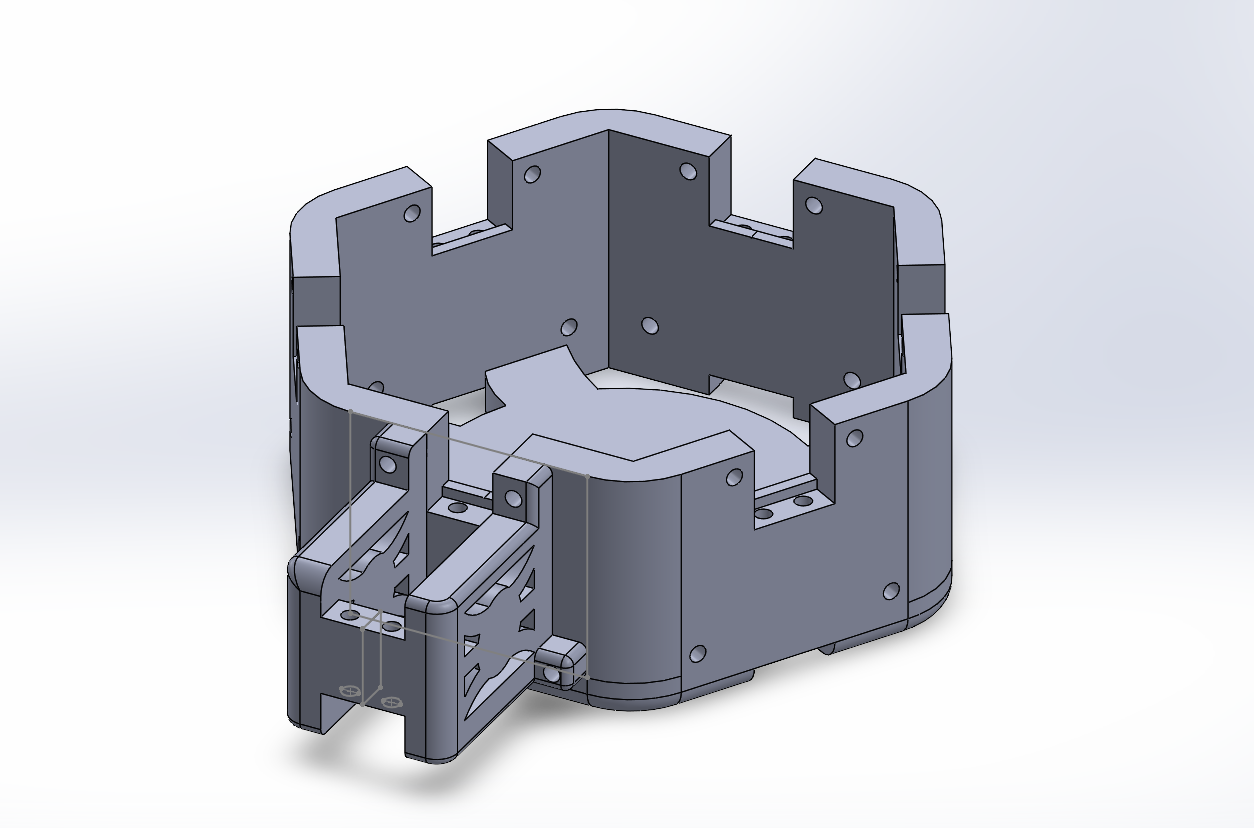

Body Parts

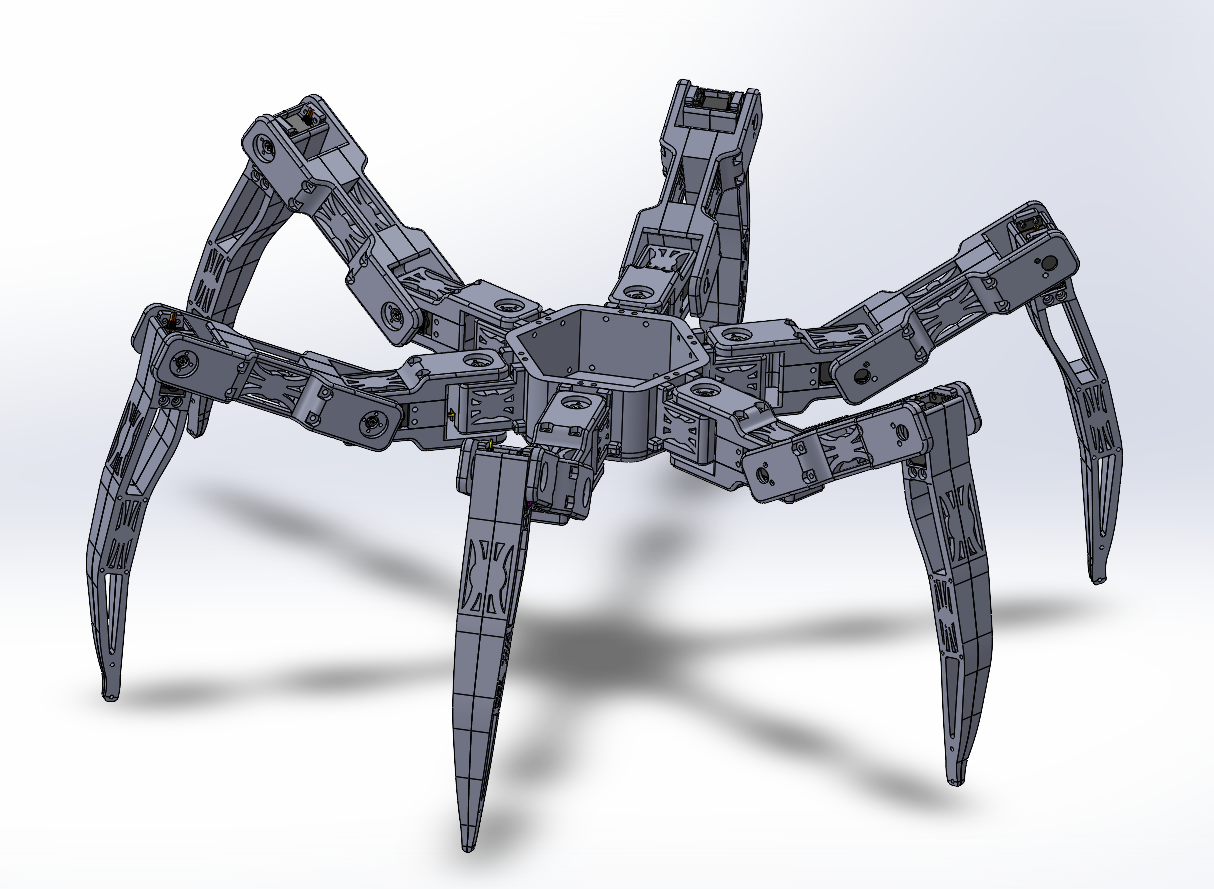

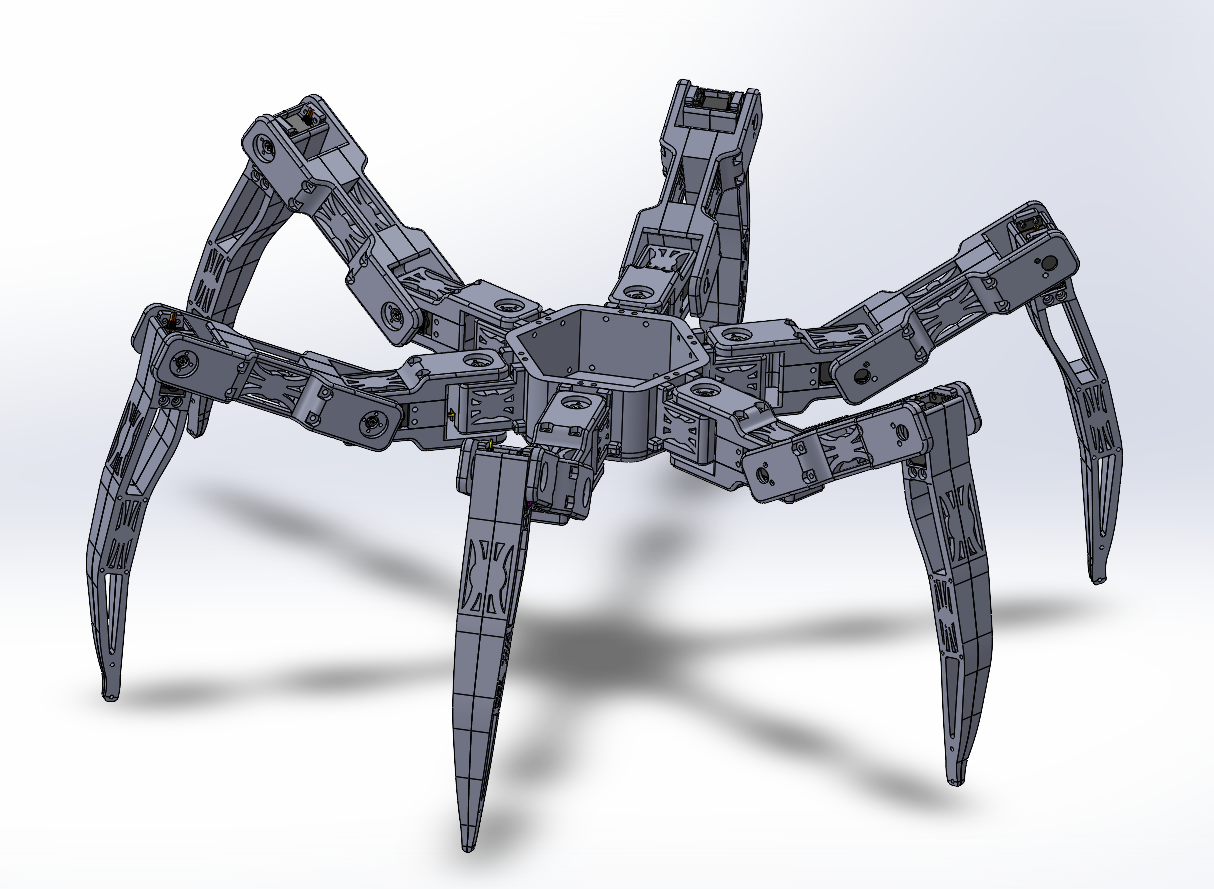

Full Assembly

Custom 3D-printed hexapod: mechanical design (coxa/femur/tibia), embedded control, and ROS2 integration. Below you’ll find photos, part breakdowns, and demo videos.

See GalleryThe purpose of the project is to build a custom hexapod, and to then implement high level features and experiment with ROS2 and Robotics focused programming.

Controller (STM32 / Raspberry Pi) → PWM/servo drivers → 18 DOF (3 per leg). Power distribution and onboard sensing (IMU, optional LiDAR) for balance and navigation.

Click any photo to view it larger.

These two videos present the full leg design and complete assembly in Solidworks.